Operation and Maintenance

IEC 61850-based Substation Automation System

Cost Effective and Flexible Substation Automation System

Background Purpose

- (Specification) Incompatible between other manufacturers’ devices.

- (Operation) No way to full use of available data (storage, utilization).

- (Cost) Equipment and labor cost reduction and shortening construction period are required

Solution

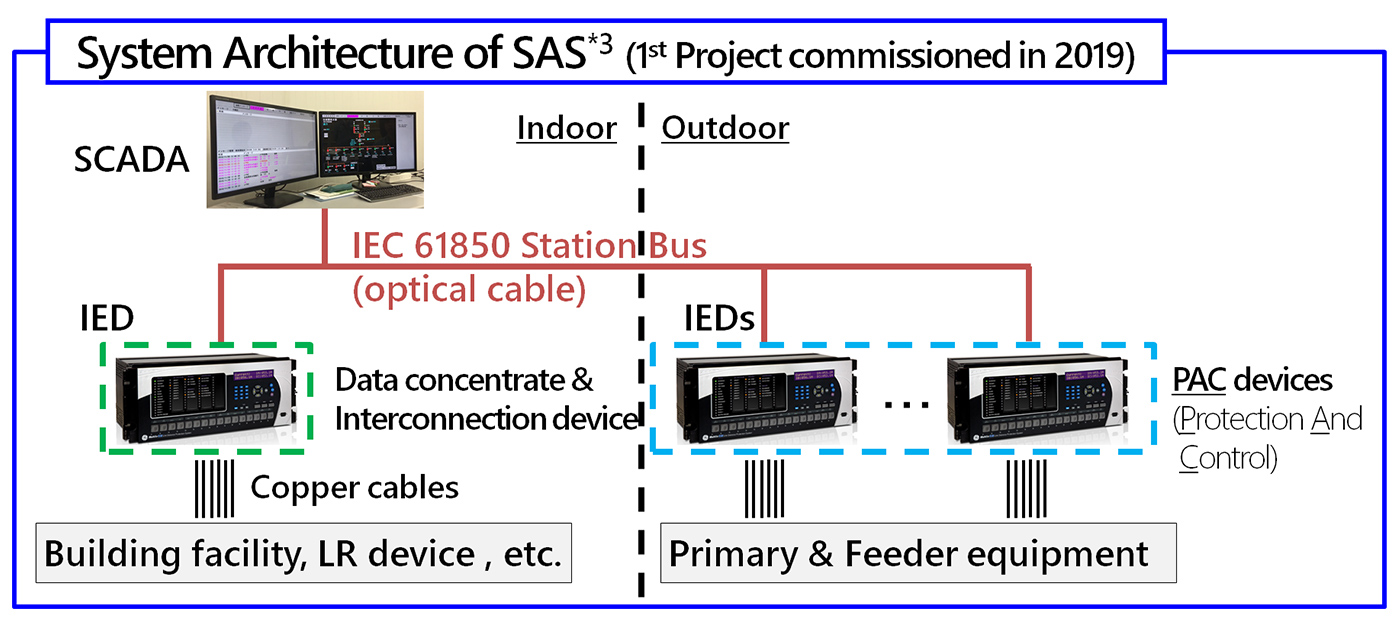

System standardization by applying IEC 61850 and using IED*1 and SCADA.*2

*1 IED: Intelligent Electronic Device

*2 SCADA: Supervisory Control And Data Acquisition

*3 SAS: Substation Automation System

Benefits

- Cost and manpower reduction (15% reduction compared with existing replacement method)

- Reduction of total amount of cupper cable laying.

- Compatibility between other manufacturers’ devices.

- Screens (layouts) of SCADA are customizable to user’s needs.

Application

- This substation automation system has functions such as control, protection relay, automatic switching control of ncoming feeders.

- SCADA provides not only real-time monitoring and control, but also efficient system operations such as collecting equipment operation history, automatic measurement.

Message

- Our first SAS project was commissioned in 2019.

- Several types of IEDs of manufacturers different from SCADA are introduced.

- This SAS were completed after repeating functional verification tests and update.

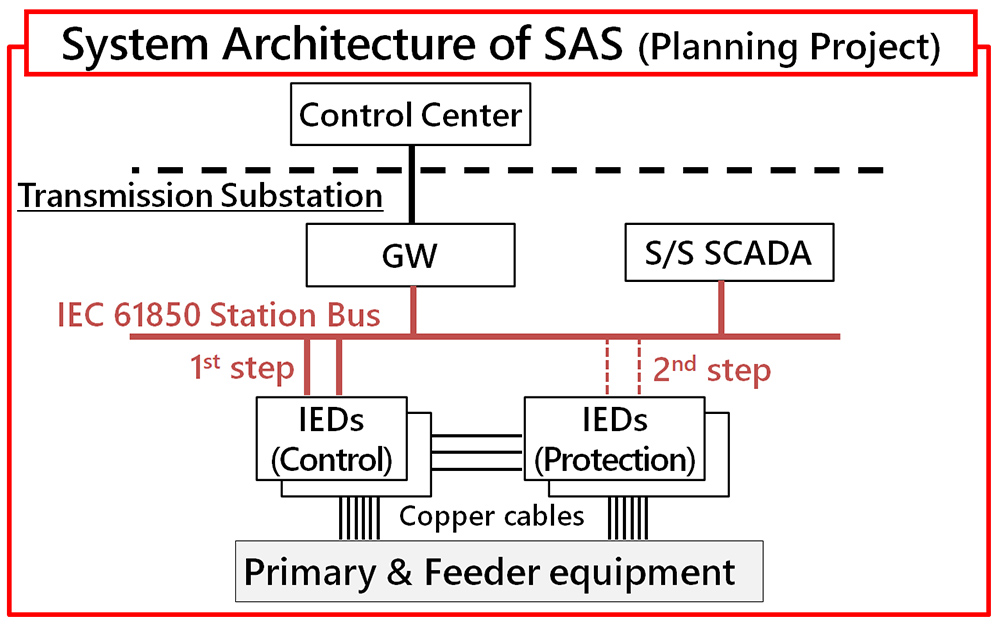

- New SAS will be introduced to substations in a few years.