Challenges

IoT Application on Substation Maintenance

Judgment of Maintenance Timing by Sensing Substation Equipment Condition Remotely

Background Purpose

At the moment, the condition of substation equipment such as circuit breaker, etc. is grasped by an inspection at power failure once every 6 years. On the other hand, if you install IoT application to these equipment, you will be able to constantly grasp the condition of each equipment in operation. This makes it possible to improve equipment analysis and save labor cost for inspection work. Furthermore, it contributes to stable supply and improvement of power quality.

[Conventional] Shutdown Maintenance every 6 Year

![[Conventional] Shutdown Maintenance every 6 Year](/english/technical/challenges/iot/img/img_02.jpg)

![[Conventional] Shutdown Maintenance every 6 Year](/english/technical/challenges/iot/img/img_03.jpg)

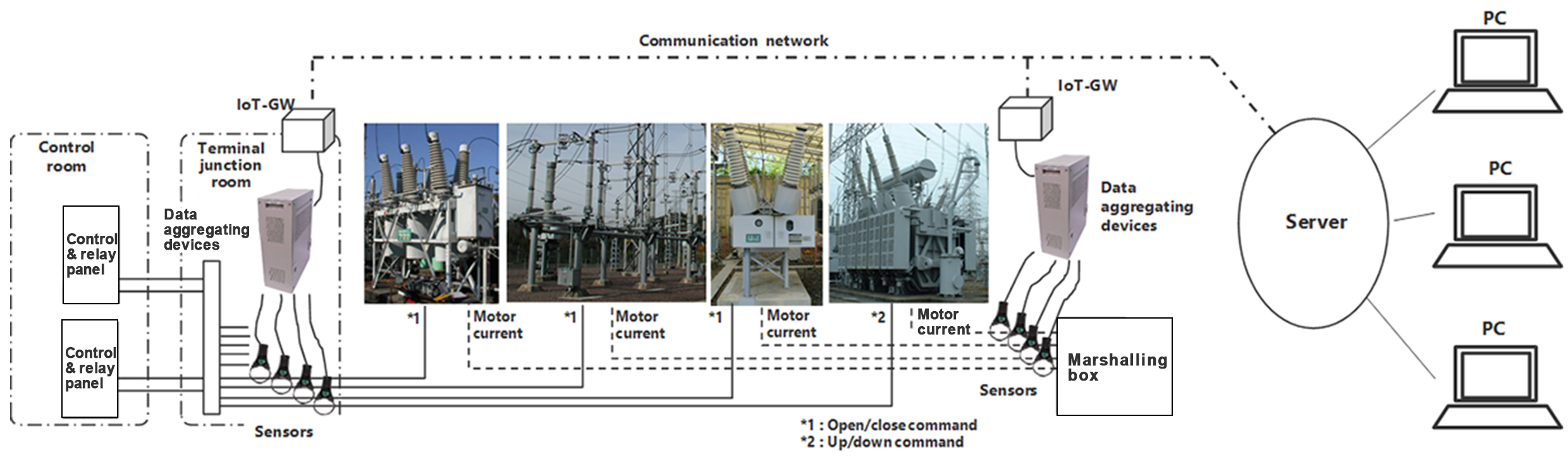

[In future] Continuous Online Monitoring by Control / Operating Current

![[In future] Continuous Online Monitoring by Control / Operating Current](/english/technical/challenges/iot/img/img_04.jpg)

![[In future] Continuous Online Monitoring by Control / Operating Current](/english/technical/challenges/iot/img/img_05.jpg)

Benefits

- Labor saving on maintenance

Continuous online monitoring, reduce shutdown maintenance - Stable supply and improvement of power quality

Grasping the condition of each equipment at any time - Low cost of devices

Creating data aggregating devices with general products - Easy device installation

Installation without shutdown by clamp type DC current sensor (Possible to install existing equipment) - High speed sampling

1 kHz sampling with 16 channels in maximum

Application

- Grasping equipment condition by current value and waveform, operating time, and so on

- Data acquisition and continuous monitoring for 25 substations in present

Message

We aim labor saving, cost reduction, stable supply and improvement of power quality on substation maintenance works by changing from TBM (Time Based Maintenance) to CBM (Condition Based Maintenance) with IoT.